Powered Industrial Turntable

This was one of the largest and most complicated mechanical projects I've worked on: a large industrial powered turntable. The goal was to synchronize material payoff with a processing machine, and ease the strain on machine operators when loading, unloading, and preparing the material.

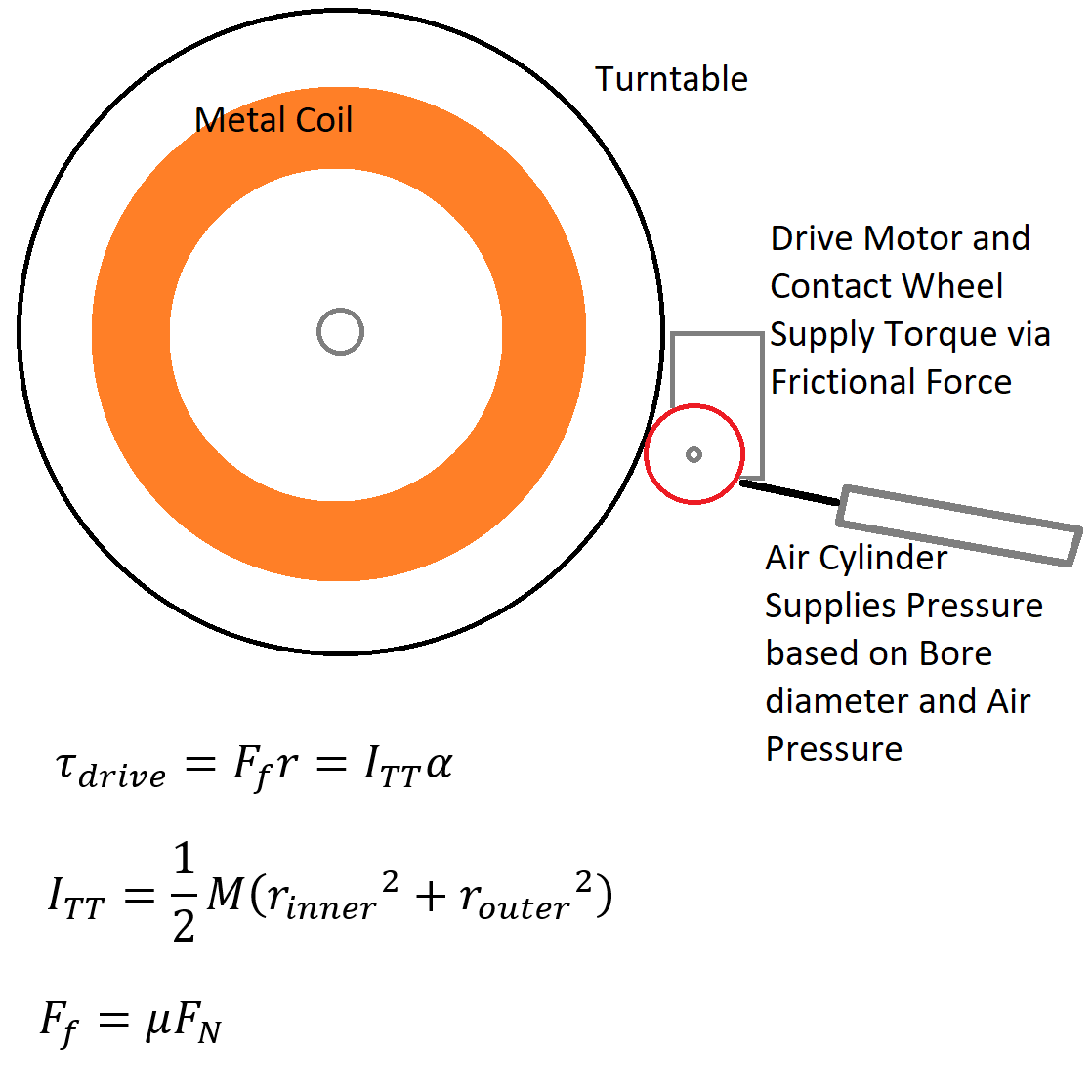

I designed a powered turntable for paying off coiled 0.75 in. diameter steel rod for industrial manufacturing environments. It accommodates harsh manufacturing conditions, has a capacity of 6000 lbs, and incorporates advanced motion controls such as regenerative braking and 3-position pneumatic controls.

It was a big learning experience for me, involving coordinating several teams of people, regulatory concerns, contractors, vendors, and a lot of hands-on assembly and installation.

Of course, the design is the property of the company, but I can include this concept drawing.

4G-Tronic Transmission Model video

This is a video presentation I made for my Master's Degree Final Project. It's about a particular transmission of a Mercedes car, which has a unique gear system. In the video, you can see each gear ratio animated in a functional model I drew in Solidworks.

The actual project revolved around outlining the hydraulic and electric controls and gear mode activations, but I generated the 3D model as an extra illustration.

Raspberry Pi Enclosure Design

When I learned that I could use a Raspberry Pi Zero 2 as a controller and camera streamer for my 3D printer at home, I set to work immediately to make it happen. Some coding is involved, but it's a relatively simple addition otherwise.

But it needs a case! There are other cases out there for download or purchase, but none fit my application well. So, after generating a model of the Raspberry Pi Zero 2 W in Solidworks, I designed a base and lid around it, checking airflow and heat dissipation along the way. Then I had a brilliant idea to add a custom mounting bracket for my printer!

Now the assembly and Raspberry Pi sit happily on the front of my 3D printer, controlling and monitoring my 3D printer, and producing a nice timelapse video for every print!

Isn't it amazing that a video like this one was taken automatically by a $15 computer!?

I ♥ 3D Modeling!

I first started learning to model in 3D during my Master's Degree. I was disappointed with my previous concept drawing methods, and decided to start with basic 3D modeling. At the time, I started with Fusion360, which is very capable, and easy to use. On the left is a concept model I drew for my product development graduate degree class.

I quickly became enamored with all the additional engineering tools available, such as body properties, cross-section views, CAM toolpath generation, and most of all, simulations! When I began using Autodesk Inventor and then Solidworks, it was like a whole new world was opened up by the toolboxes and additional precision of the models and techniques.

Van de Graff Generator Model

The first certification I received was for Autodesk Inventor. At first, I learned so much from practicing modelling objects from my surroundings. Then I thought to challenge myself with an actual complex machine in the form of a Van de Graff generator I had in my classroom.

I started out modeling every piece from stratch, taking apart the machine and measuring every component. The motor and pushbutton, however, I learned I could download models from the manufacturers to add to the design. By the time I was finished, I'd learned so much, I decided I should go for the Inventor Certified User test. After building this thing assembly for practice, the test was pretty easy!